-

Call Us Now

+91-9820325057 -

Opening Hours

Mon - Sat 09.00 - 06.30

Tensile Fabric Explained | Tensile Membranes & Tensile Structures in India

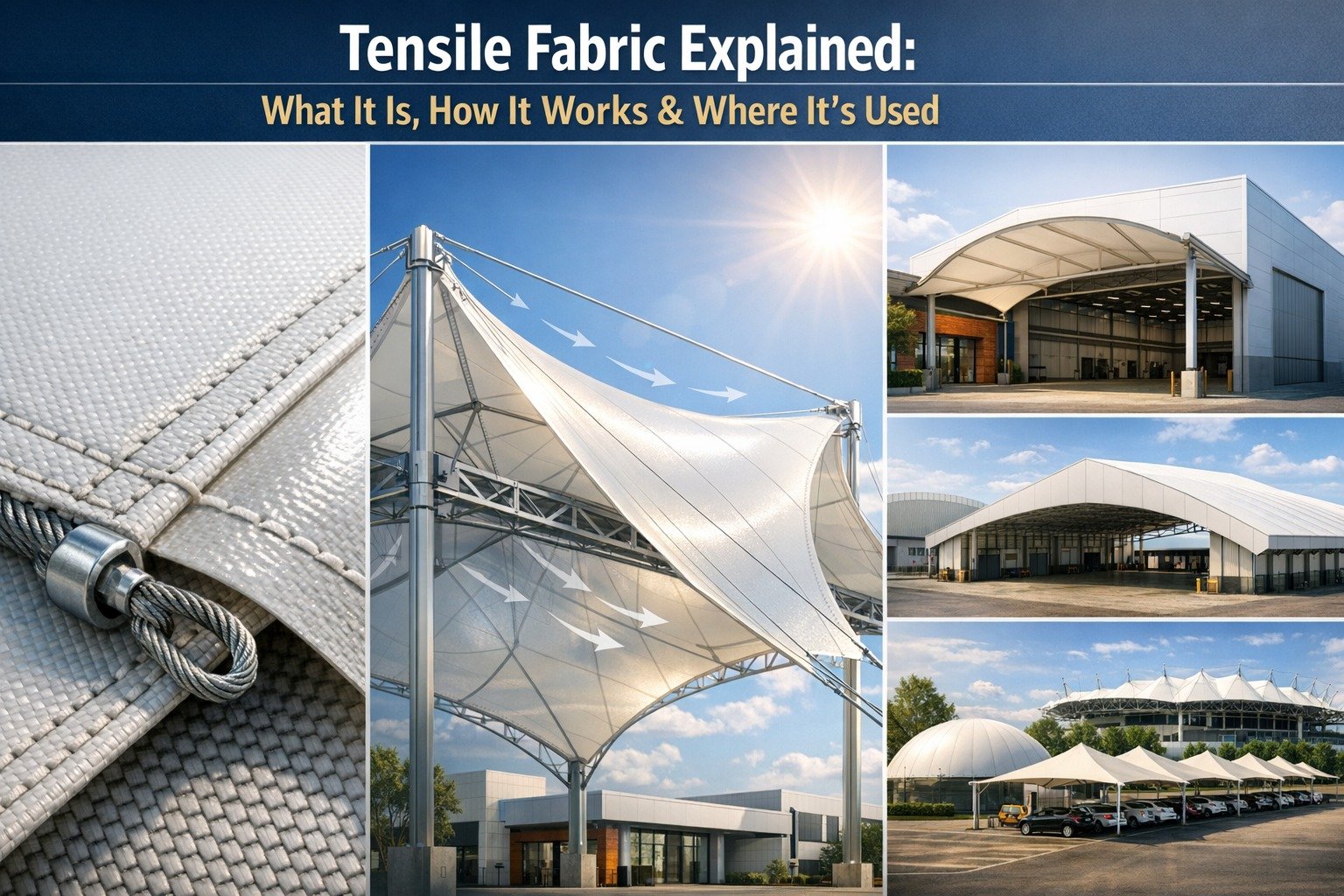

Tensile fabric has changed the way modern structures are built. Instead of using heavy materials like concrete slabs or traditional metal roofing systems, tensile fabric allows designers and industries to create strong, lightweight, and visually modern structures using engineered membranes. Across India and global markets, tensile membranes are now widely used in architectural roofing, industrial coverings, and large-spantensile structures. The reason is simple: tensile fabric offers durability, speed, and flexibility while performing well in harsh weather. Let’s explore what tensile fabric really is, how it works, and where it is used.

Table of contents :

- What Is Tensile Fabric?

- How Tensile Membranes Work

- Where Tensile Fabric Is Used

- What to Look for in a High-Quality Tensile Fabric

- Conclusion

What Is Tensile Fabric?

Tensile fabric is a technical membrane designed to be stretched and held under tension. It is not a decorative textile — it is an engineered construction material built to handle wind loads, rain, sunlight, and structural stress.

Most tensile fabric is produced using a polyester base fabric coated with PVC. This PVC coating provides:

waterproofing

UV resistance

chemical resistance

weldable seam strength

smooth surface finish

This combination makes tensile membranes ideal for long-term outdoor use.

How Tensile Membranes Work

The core working principle behind tensile membranes is tension-based load distribution. Instead of resisting loads with weight (like traditional roofing), tensile structures resist loads through their shape and tension.

When a tensile membrane is stretched correctly:

wind pressure spreads across the surface

rainwater drains through curved geometry

structural movement is absorbed without cracking

large areas can be covered with fewer support columns

This is why tensile structures are popular for both architecture and industrial use.

Why Tensile Structures Are So Popular

Tensile structures offer several advantages that make them ideal for modern infrastructure:

Lower structural weight

Fast installation

High design flexibility

Clear-span coverage

Modern appearance

Long service life

This is especially valuable in projects where time and cost matter, such as warehouses, parking shades, and public infrastructure.

Where Tensile Fabric Is Used

Tensile fabric is widely used across multiple industries. Some of the most common applications include:

1) Architectural Canopies

Used in malls, airports, hotels, schools, and public entrances for shade and rain protection.

2) Walkway Roofing

Tensile membranes create elegant covered walkways without heavy construction.

3) Parking Shade Structures

One of the most common tensile structure applications due to fast installation and high UV protection.

4) Industrial Roofing

Warehouses, logistics hubs, and temporary industrial spaces use tensile fabric roofing to cover large areas efficiently.

5) Protective Covers

PVC-coated tensile fabric is also used for:

truck tarpaulins

agricultural covers

equipment covers

temporary shelters

What to Look for in a High-Quality Tensile Fabric

For long-term performance, tensile fabric must be selected carefully. A high-quality tensile membrane should offer:

high tensile strength

strong tear resistance

UV stability

strong seam welding

long-term flexibility

anti-fungal properties

Low-grade membranes may fail early due to coating cracks, seam issues, or weather damage.

Conclusion

Tensile fabric is one of the most reliable modern building materials for lightweight roofing and coverings. With correct engineering and high-quality tensile membranes, tensile structures can deliver strong performance for years while offering a clean and modern appearance.

📞 Contact Us Today

For inquiries, samples, or technical specifications:

LUCKY INTERNATIONAL

📱 Phone: +91-86553 57854 / +91-9820325057

📧 Email: info@luckyinternational.net

🌐 Website: www.luckyinternational.net

Get Your Free Quote Today!

Tell us about your project needs and we'll provide a custom quote.