-

Call Us Now

+91-9820325057 -

Opening Hours

Mon - Sat 09.00 - 06.30

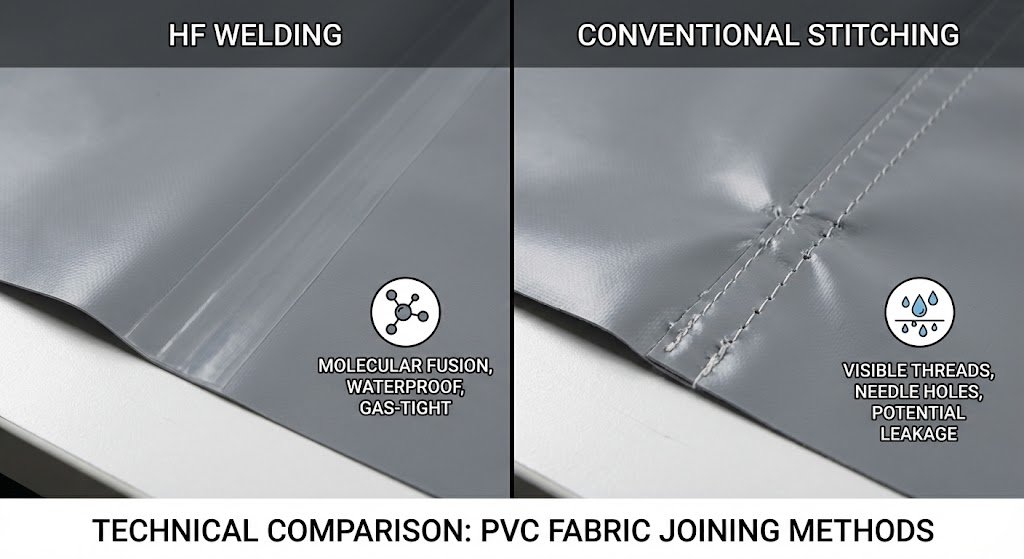

How Welding Quality Affects Fabric Life: HF Welding vs Conventional Stitching

In high-performance applications such as tensile structures, biogas storage balloons, tarpaulins, industrial covers, awnings, and architectural membranes, the durability of PVC coated fabric depends not only on fabric quality — but also on how the fabric panels are joined.

Two commonly used joining methods dominate the industry today: HF (High Frequency) Welding and Conventional Stitching. While both are used widely, their impact on fabric lifespan, gas retention, waterproofing, and long-term performance is drastically different.

At LUCKY INTERNATIONAL, we manufacture European-quality PVC coated fabrics in exclusive partnership with SIOEN INDUSTRIES, BELGIUM, engineered specifically to perform optimally with advanced HF welding technology. This blog explains why welding quality matters and how HF welding outperforms conventional stitching in critical applications.

Table of contents :

- Why Joining Technology Matters in PVC Coated Fabrics

- What Is HF (High Frequency) Welding?

- What Is Conventional Stitching?

- HF Welding vs Conventional Stitching: A Performance Comparison

- Why HF Welding Is Critical for Biogas & Tensile Applications

- LUCKY INTERNATIONAL: Engineered for HF Welding Excellence

- Conclusion: Welding Quality Defines Fabric Performance

Why Joining Technology Matters in PVC Coated Fabrics

PVC coated fabrics are designed to withstand:

High tensile stress

Continuous outdoor exposure

UV radiation and harsh weather

Gas pressure (biogas and air structures)

Water, chemicals, and pollutants

However, weak joints can compromise even the best fabric.

Poor joining methods can lead to:

Seam leakage

Reduced fabric life

Delamination near joints

Gas loss in biogas balloons

Water seepage and premature failure

That is why welding quality is as important as fabric quality.

What Is HF (High Frequency) Welding?

HF Welding, also known as Radio Frequency (RF) Welding, uses high-frequency electromagnetic waves to melt and fuse PVC layers together at a molecular level.

Instead of puncturing the fabric, HF welding:

Softens the PVC coating

Bonds layers into a single, seamless joint

Creates joints as strong as or stronger than the fabric itself

This makes HF welding the preferred joining method for premium PVC coated fabrics.

What Is Conventional Stitching?

Conventional stitching uses threads and needles to mechanically join fabric panels.

While this method may be cheaper initially, it introduces several long-term disadvantages:

Needle holes weaken the fabric

Threads degrade faster than PVC

Seams are vulnerable to water, gas, and UV exposure

Stitching is still used in low-cost or short-term applications, but it is not suitable for high-performance or long-life structures.

HF Welding vs Conventional Stitching: A Performance Comparison

1. Seam Strength & Durability

HF Welding

Seam becomes part of the fabric

No perforation or structural damage

Extremely high tensile and peel strength

Conventional Stitching

Fabric is punctured by needles

Stress concentration around stitch holes

Higher risk of tearing under load

Winner: HF Welding

2. Waterproof & Gas-Tight Performance

HF Welding

100% waterproof seams

Excellent gas retention

Ideal for biogas balloons and gas holders

Conventional Stitching

Water can seep through stitch holes

Gas leakage over time

Requires sealants (temporary solution)

Winner: HF Welding

3. Fabric Life & Long-Term Reliability

HF Welding

Seam life equals fabric life

No thread degradation

Maintains integrity for years

Conventional Stitching

Threads deteriorate due to UV and chemicals

Seams fail before fabric

Shorter overall lifespan

Winner: HF Welding

4. Resistance to Harsh Indian Climate

HF Welding

Excellent performance in heat, humidity, and monsoon

No loosening or seam expansion

Conventional Stitching

Threads shrink, loosen, or break

Seams weaken in extreme weather

Winner: HF Welding

Why HF Welding Is Critical for Biogas & Tensile Applications

Applications such as biogas storage balloons, tensile roofs, membrane structures, and industrial enclosures demand:

Zero leakage

High internal pressure resistance

Long service life

Minimal maintenance

HF welding ensures:

Superior gas retention

Leak-free seams

Lower operational losses

Higher ROI over the fabric lifecycle

That is why HF welding is the industry standard for premium membrane projects worldwide.

LUCKY INTERNATIONAL: Engineered for HF Welding Excellence

At LUCKY INTERNATIONAL, our PVC coated fabrics are specifically engineered to deliver maximum performance with HF welding.

What Sets Us Apart:

Exclusive partnership with Sioen Industries, Belgium

Uniform PVC coating for consistent welding quality

Excellent adhesion between PVC and base fabric

High seam strength and durability

Proven performance in biogas, tensile, and industrial projects

Our membranes are trusted across India for projects that demand long life, safety, and performance without compromise.

HF Welding = Lower Maintenance & Higher Savings

While HF welding may have a higher initial cost, it offers:

Longer fabric life

Fewer repairs

Minimal downtime

Reduced gas and water losses

Better structural safety

In the long run, HF welded PVC coated fabric is far more cost-effective than stitched alternatives.

Conclusion: Welding Quality Defines Fabric Performance

No matter how premium a PVC coated fabric is, poor joining can destroy its performance.

If you want:

Longer fabric life

Leak-free operation

Superior gas retention

Reliable performance in Indian conditions

HF welding is the clear winner over conventional stitching.

And when combined with European-quality PVC coated fabrics from LUCKY INTERNATIONAL, the result is world-class performance built to last.

Contact Us Today

LUCKY INTERNATIONAL

Phone: +91-9820325057

Email: info@luckyinternational.net

Website: www.luckyinternational.net

LUCKY INTERNATIONAL — European Technology. Trusted Performance. Built to Last.

Get Your Free Quote Today!

Tell us about your project needs and we'll provide a custom quote.