-

Call Us Now

+91-9820325057 -

Opening Hours

Mon - Sat 09.00 - 06.30

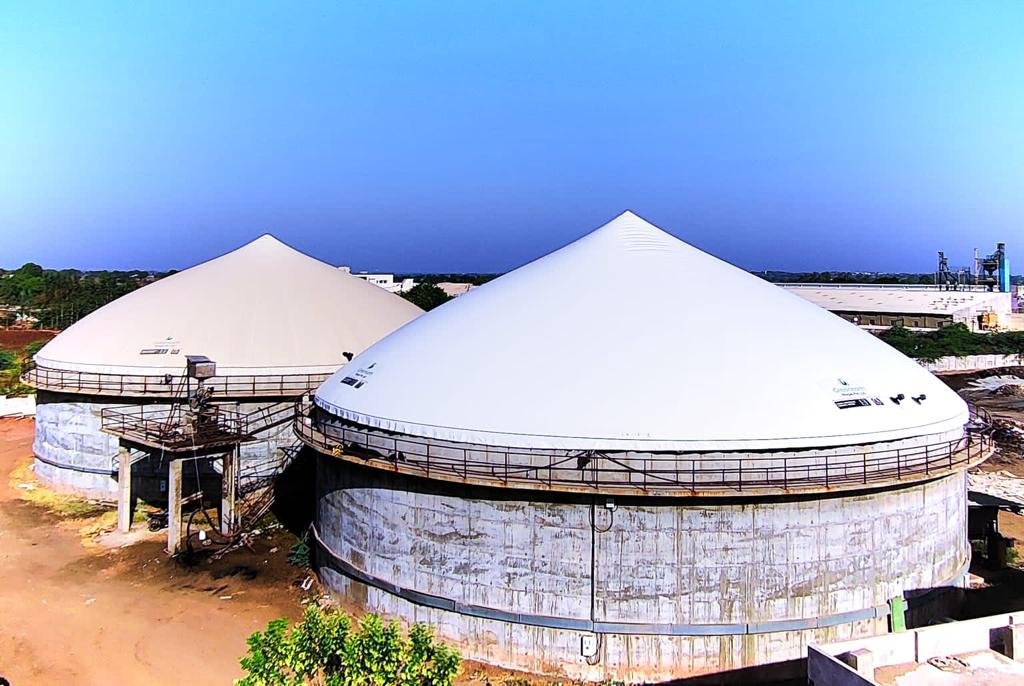

How Premium PVC-Coated Fabrics Improve Biogas Balloon Performance and Safety

Introduction: Why Quality PVC Fabric Matters in Biogas Systems

In India’s growing renewable energy sector, biogas plants are becoming an essential part of sustainable waste management and clean energy generation. However, one critical component often determines a system’s long-term success — the biogas balloon or gas storage dome.

At LUCKY INTERNATIONAL MEMBRANES, we manufacture high-quality PVC-coated fabrics in India through our exclusive partnership with SIOEN INDUSTRIES (Belgium) — one of the world’s leading producers of technical textiles.

The quality of your biogas balloon fabricbiogas balloon fabric can directly impact its gas retention, safety, and lifespan. Let’s explore how premium European PVC-coated fabrics can significantly enhance biogas performance compared to local alternatives.

Table Of Contents:

- Gas-Tightness and Leak Prevention

- Superior UV and Weather Resistance

- High Mechanical Strength for Pressure Stability

- Fire Retardancy and Safety Standards

- Seam Weldability and Installation Efficiency

- Proven European Quality — Now in India

- Conclusion: The LUCKY INTERNATIONAL Advantage

Gas-Tightness and Leak Prevention

The main function of a biogas balloon is to store methane gas safely and efficiently.

Premium PVC-coated fabrics like those supplied by LUCKY INTERNATIONAL (powered by SIOEN) have superior gas impermeability, preventing methane leakage even under high internal pressure.

The multi-layer coating technology ensures uniform surface density, minimizing the chances of micro-leaks.

In contrast, low-quality or locally produced PVC fabrics may contain porous layers or weak adhesion, causing gas seepage over time.

✅ Result: Enhanced biogas retention, stable pressure, and improved energy efficiency.

Superior UV and Weather Resistance

Biogas plants often operate in harsh outdoor conditions — from intense sunlight to heavy rainfall and humidity.

European PVC-coated fabrics from SIOEN are engineered with UV stabilizers and anti-fungal additives, protecting them from sun damage, discoloration, and material degradation.

LUCKY INTERNATIONAL’s PVC fabrics maintain their mechanical strength and flexibility for 10–15 years, even in tropical environments.

🟩 Longer fabric lifespan = lower replacement costs + reduced maintenance downtime.

High Mechanical Strength for Pressure Stability

During gas production, internal pressure inside the balloon fluctuates. The fabric must handle this without stretching or tearing.

LUCKY INTERNATIONAL PVC membranes are built with high-tenacity polyester yarns and reinforced coating layers, ensuring excellent tensile and tear strength.

These fabrics are designed to maintain dimensional stability even under continuous gas load.

Local fabrics with weaker yarn quality often lose elasticity, leading to balloon deformation or ruptures.

💪 Premium fabric = better structural integrity = enhanced biogas storage safety.

Fire Retardancy and Safety Standards

Safety is non-negotiable in biogas systems, as methane is a flammable gas.

SIOEN-engineered PVC-coated fabrics, supplied by LUCKY INTERNATIONAL, comply with global B1/M2 fire-retardant standards.

They resist ignition and self-extinguish quickly, preventing fire spread in case of electrical or mechanical faults.

Low-cost local fabrics rarely meet certified fire-safety standards, increasing operational risks.

🔥 LUCKY INTERNATIONAL PVC fabrics = certified fire safety = peace of mind for operators.

Seam Weldability and Installation Efficiency

A reliable biogas balloon depends not only on the fabric but also on how it’s welded and sealed.

LUCKY INTERNATIONAL PVC membranes have excellent weldability, making them ideal for high-frequency and hot-air welding.

The consistent coating thickness ensures airtight seams, reducing the chances of leaks after installation.

This also speeds up installation and lowers labor costs for plant builders.

⚙️ Better weldability = stronger seams = fewer gas losses.

Proven European Quality — Now in India

Thanks to LUCKY INTERNATIONAL’s exclusive partnership with SIOEN INDUSTRIES (Belgium), Indian biogas manufacturers now have access to European-grade PVC-coated fabrics without import delays or cost barriers.

Every roll of LUCKY INTERNATIONAL PVC fabric is certified, tested, and traceable.

Meets EN ISO 9001, REACH compliance, and UV durability standards.

Trusted by global biogas plant manufacturers and EPC contractors.

🌍 European technology, made available locally — for stronger, safer biogas systems.

Conclusion: The LUCKY INTERNATIONAL Advantage

When it comes to biogas balloon performance and safety, the fabric you choose defines your plant’s success.

By choosing LUCKY INTERNATIONAL PVC-coated fabrics, you ensure:

✅ Leak-free gas storage

✅ Superior weather and UV resistance

✅ Certified fire retardancy

✅ Easy installation and long service life

With LUCKY INTERNATIONAL MEMBRANES and SIOEN INDUSTRIES, you’re investing in European innovation, Indian expertise, and long-term reliability — all in one solution.

Get Your Free Quote Today!

Tell us about your project needs and we'll provide a custom quote.