-

Call Us Now

+91-9820325057 -

Opening Hours

Mon - Sat 09.00 - 06.30

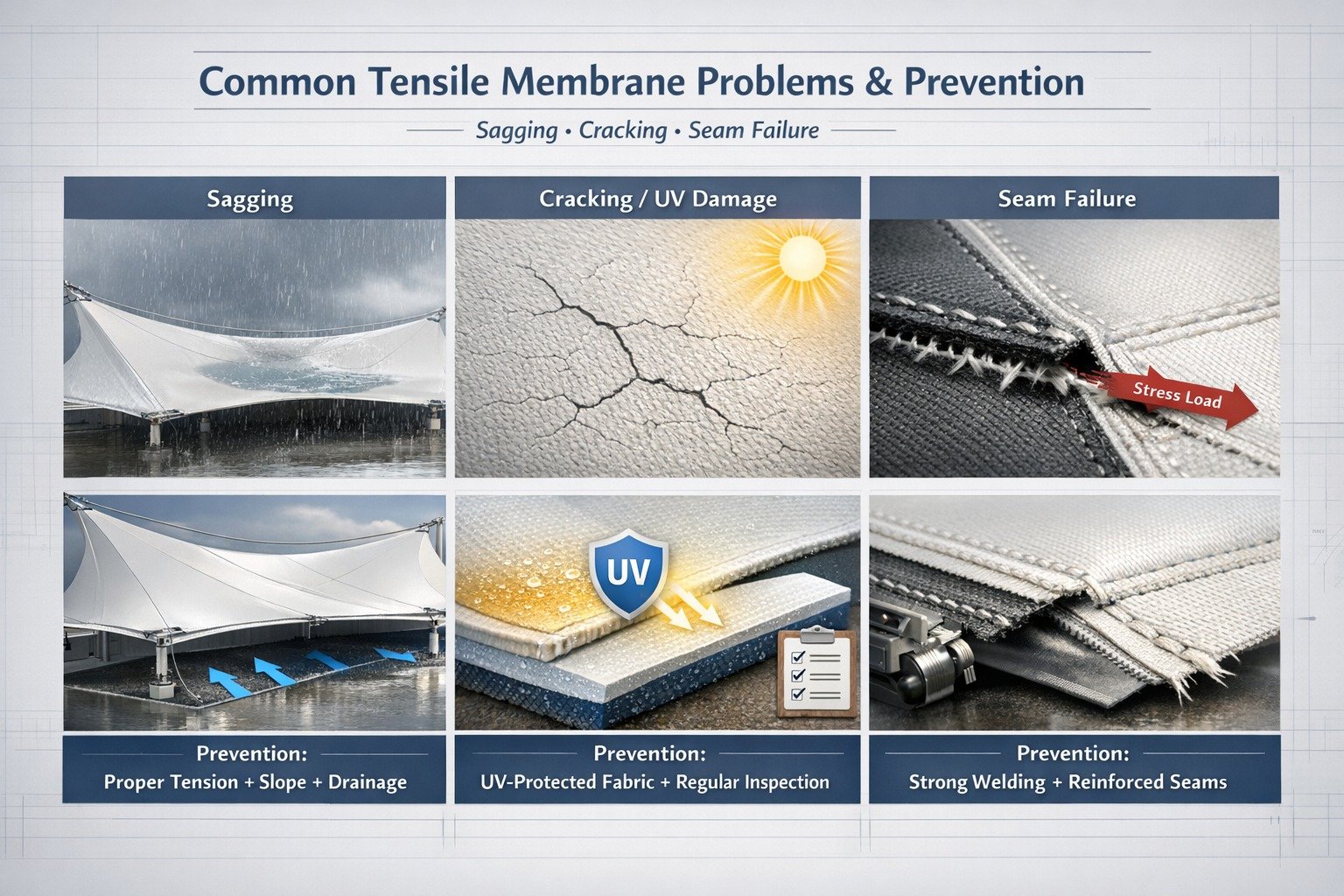

Common Tensile Membrane Problems (Sagging, Cracking, Seam Failure) & How to Prevent Them

Biogas plants are becoming more common across India due to rising energy demand and the push for sustainable solutions. A key part of these systems is reliable gas storage—and that’s where the biogas balloon plays an important role.

Outdoor tensile structures are widely used across India for parking shades, entrance canopies, walkway covers,

stadium roofing, and industrial shelters. They are lightweight, modern, and ideal for large-span roofing.

But to ensure long-term performance, it’s important to understand the common problems that occur in tensile membranes—and how to prevent them.

In this blog, we’ll cover the most common issues in tensile roofs and tensile structures such as sagging, cracking, and seam failure.

Table of contents :

- Common issues in tensile roofs

- Other Issues in Tensile Structures

- Tensile Fabric Solutions from LUCKY INTERNATIONAL

1) Sagging in Tensile Roofs

Sagging occurs when the membrane loses tension and develops loose areas. This can lead to water pooling during rain.

Causes include:

low-quality tensile fabric

poor tensioning during installation

weak anchoring systems

fabric stretching over time

Prevention:

Use a high-strength tensile membrane with stable dimensional performance, and ensure correct tensioning and anchoring during installation.

2) Cracking and Coating Damage

Cracking is common in membranes with poor UV protection, especially under Indian heat.

Causes include:

low UV resistance

inferior PVC coating

lack of protective topcoat

harsh cleaning chemicals

Prevention:

Choose UV-stabilized tensile membranes, preferably with a top lacquer for better surface durability and cleanability.

3) Seam Failure

Seam failure happens when welded joints weaken or open over time.

Causes include:

poor welding quality

incorrect seam design

fabric with weak coating adhesion

uneven load distribution

Prevention:

Use fabric with good weldability and ensure professional welding techniques with proper reinforcement.

Other Issues in Tensile Structures

Some additional issues include:

fading and discoloration

fungal growth

staining and dirt accumulation

edge tearing at clamp points

Most of these problems can be avoided by selecting the right tensile fabric and ensuring correct fabrication standards.

Tensile Fabric Solutions from LUCKY INTERNATIONAL

At LUCKY INTERNATIONAL, we supply premium tensile fabric and tensile membranes for outdoor tensile structures across India. Our focus is on reliable membrane performance, long lifespan, and consistent quality.

📞 Contact Us Today

For inquiries, samples, or technical specifications:

LUCKY INTERNATIONAL

📱 Phone: +91-86553 57854 / +91-9820325057

📧 Email: info@luckyinternational.net

🌐 Website: www.luckyinternational.net

Get Your Free Quote Today!

Tell us about your project needs and we'll provide a custom quote.